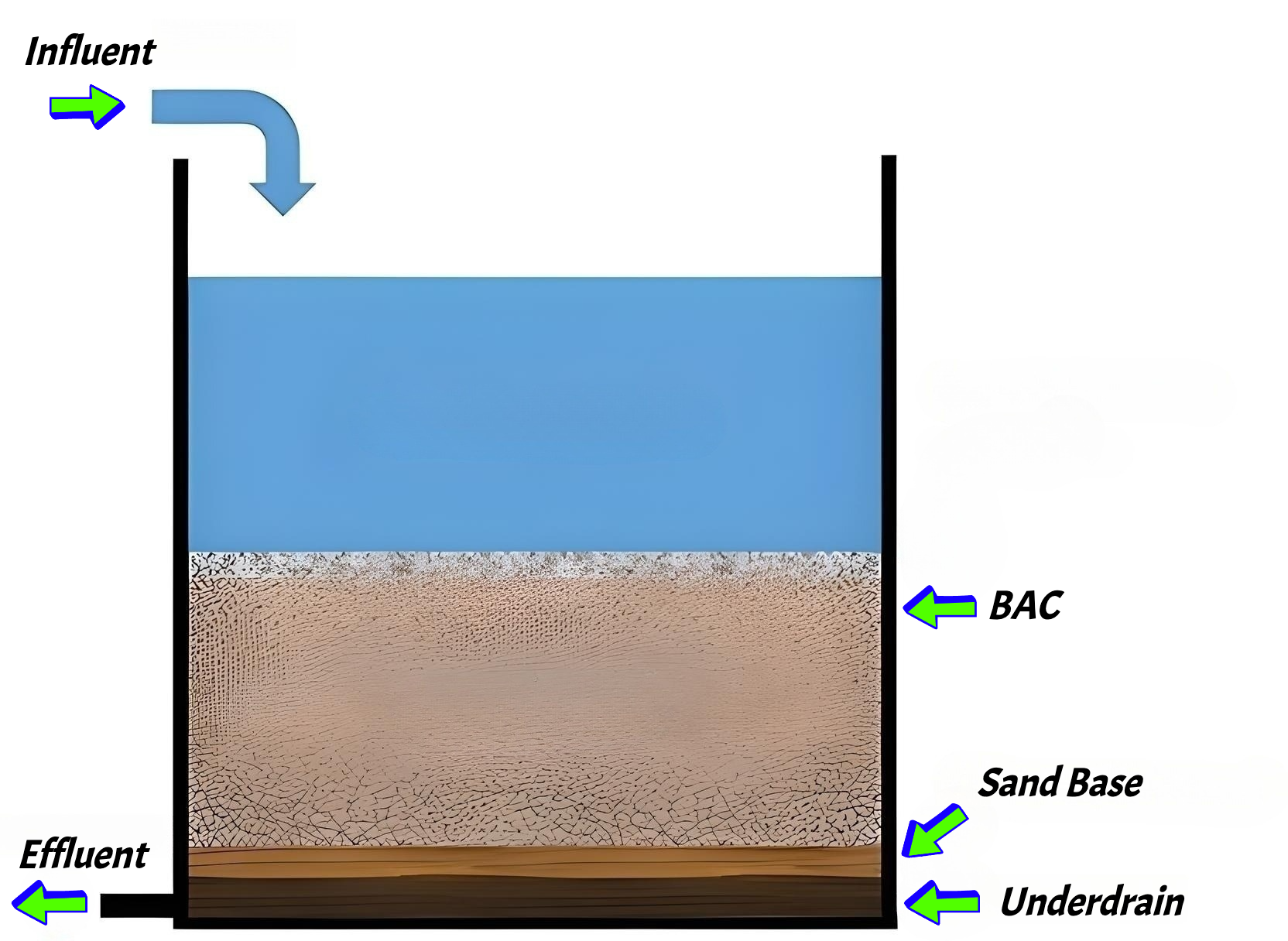

6. BAC System Operation and Maintenance

Effective operation and regular maintenance of Biological Activated Carbon (BAC) systems are essential for ensuring long-term performance, maintaining water quality, and preventing costly downtime. Operators must be familiar with all aspects of the BAC system, from daily operations to troubleshooting common issues and implementing a long-term media management plan. This section covers key aspects of BAC operation, including the backwash process, performance monitoring, maintenance best practices, and long-term media management.

6.1 Detailed Backwash Process

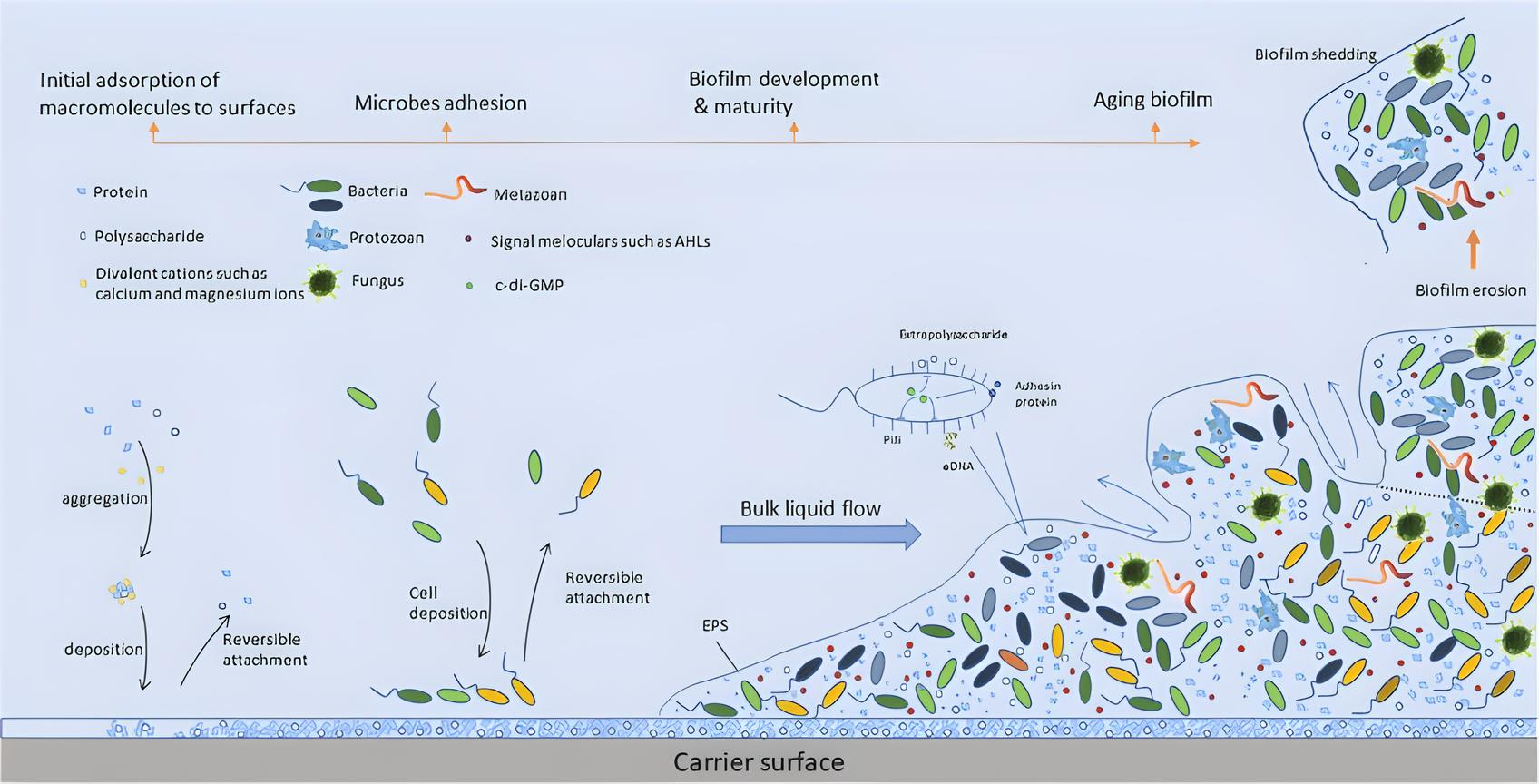

The backwash process is critical for maintaining BAC system performance. Over time, particulate matter, biofilm, and other debris accumulate on the surface and within the GAC media, leading to increased headloss, reduced flow capacity, and diminished filtration efficiency. A well-executed backwash cycle cleans the filter media, restores flow, and prolongs the operational life of the system.

The backwash process typically involves four key stages:

- Air Scour: Compressed air is introduced into the filter bed, agitating the GAC media and loosening particulates and biofilm that have accumulated on the surface. The air scour step is crucial for preventing media fouling and ensuring thorough cleaning of the filter media. Proper air scour intensity and duration must be adjusted based on the system’s design and the level of fouling observed.

- Low-Rate Water Backwash: After the air scour phase, a low-rate water backwash is initiated to flush out the loosened particulates. This step helps remove fine solids and biofilm from the filter bed without causing excessive expansion of the media, which could lead to media loss.

- High-Rate Water Backwash: The water flow rate is increased to fully expand the media bed and remove any remaining particulates. This phase is essential for restoring the filter's capacity and resetting its filtration efficiency. The high-rate backwash ensures that all layers of the GAC media are cleaned, preventing fouling and uneven flow distribution.

- Rinse: The final rinse phase uses a moderate flow rate to remove any residual particles and return the media bed to its normal configuration. This step is important for ensuring that the filter is ready for operation after the backwash process.

Optimal backwash rates are typically measured in gallons per minute per square foot (gpm/ft²) and should be tailored to the specific needs of the BAC system. Excessive backwash rates can result in media loss, while insufficient rates may not fully clean the media. Operators should monitor the filter's performance after each backwash cycle to ensure that headloss and flow rates return to acceptable levels.

6.2 Performance Monitoring and Instrumentation

To ensure BAC systems operate efficiently, operators must monitor several key performance indicators. These indicators provide real-time data that help operators detect potential issues early and make necessary adjustments before system performance degrades. Instrumentation plays a vital role in monitoring these indicators.

- Headloss: Headloss is the pressure difference between the influent and effluent sides of the BAC filter. As particulates and biofilm accumulate in the media bed, the pressure required to maintain flow increases, leading to higher headloss. Monitoring headloss allows operators to determine when a backwash is required and ensures that the system is operating within its design parameters.

- Instruments used: Differential pressure sensors are installed at the influent and effluent sides of the filter to measure headloss in real time. These sensors must be regularly calibrated to provide accurate data. A sudden spike in headloss may indicate air binding, media fouling, or a blockage in the system, all of which require immediate attention.

- Total Organic Carbon (TOC) Removal: TOC removal is a key performance indicator that measures the system’s ability to remove organic contaminants from the water. High TOC removal rates indicate that the biological activity within the BAC filter is functioning properly.

- Instruments used: Online TOC analyzers continuously monitor TOC levels at the influent and effluent, providing real-time data on the system’s efficiency. TOC data helps operators adjust operational parameters, such as Empty Bed Contact Time (EBCT), to optimize contaminant removal.

- Flow Rates: Maintaining consistent flow rates is essential for ensuring the proper function of a BAC system. Significant changes in flow rates can affect EBCT and lead to uneven media fouling or biofilm development.

- Instruments used: Flow meters provide real-time data on the volume of water passing through the filter. Sudden fluctuations in flow rates may indicate pump failures, valve malfunctions, or blockages in the filter media.

6.3 Long-Term Media Management

Granular activated carbon (GAC) media is the heart of a BAC system, and managing the media's long-term performance is crucial for ensuring the system's overall efficiency. GAC media gradually loses its adsorption capacity over time due to the accumulation of particulates, biofilm growth, and physical abrasion. Operators must regularly assess the condition of the media and determine when replacement or regeneration is necessary.

- Media Lifespan: The lifespan of GAC media depends on several factors, including the quality of the influent water, the rate of organic contaminant loading, and the effectiveness of the backwash process. As the media ages, its adsorption capacity diminishes, leading to reduced TOC removal and increased backwash frequency. Regular monitoring of TOC removal and headloss can help operators assess when the media needs to be replaced.

- Media Replacement: Operators should plan for media replacement when the GAC's adsorption capacity is significantly reduced, and performance indicators show a decline in TOC removal. Media replacement schedules vary based on system design and operational parameters but are typically required every 2–5 years for most BAC systems.

- Media Regeneration: In some cases, GAC media can be thermally regenerated to restore its adsorption capacity. This process involves heating the media to remove accumulated contaminants, allowing the media to be reused. While more cost-effective than complete media replacement, thermal regeneration may result in some loss of carbon mass, reducing the media’s overall lifespan.

Operator’s Tip: Track TOC removal and headloss trends to know when it’s time for media replacement—don’t wait for a crisis!

6.4 Troubleshooting Common Operational Issues

Despite careful maintenance, BAC systems can encounter operational issues that require troubleshooting. Understanding the causes of these issues and how to address them is critical for maintaining system performance.

- Air Binding: Air binding occurs when air becomes trapped in the filter bed, reducing flow capacity and increasing headloss. This problem can occur due to improper backwashing or the release of gases from biofilm activity. To resolve air binding, operators can perform a hydraulic bump or adjust the backwash sequence to remove trapped air.

- Media Fouling: Media fouling occurs when fine particulates, organic matter, or biofilm block the filter media, leading to increased headloss and reduced contaminant removal. Regular optimization of the backwash process can help prevent media fouling. Operators should also consider adjusting backwash intensity and frequency based on the level of fouling observed.

- Biological Upsets: Disruptions in biofilm activity, such as exposure to disinfectants or sudden changes in water chemistry, can reduce the BAC system’s ability to remove organic contaminants. To mitigate biological upsets, operators should ensure that disinfectants are neutralized before entering the BAC filter and monitor the system’s dissolved oxygen levels.

Key Concept: Most BAC headaches boil down to air binding, fouling, or biofilm upsets—use trend data and your senses to catch them early!

6.5 Maintenance Best Practices and Preventive Maintenance Plan

A comprehensive preventive maintenance plan is essential for ensuring the long-term reliability of BAC systems. Regular maintenance helps prevent unexpected failures, optimizes system performance, and reduces the need for emergency repairs. Key components of a preventive maintenance plan include:

- Valve and Pump Maintenance: Valves and pumps should be inspected regularly for leaks, wear, and blockages. Regular lubrication of pump bearings, seal replacement, and flow testing help prevent premature failures and ensure consistent operation.

- Instrumentation Calibration: Flow meters, pressure sensors, TOC analyzers, and other monitoring instruments must be calibrated at regular intervals to ensure accurate readings. Accurate data from these instruments allows operators to make informed decisions about system performance and maintenance needs.

- Underdrain System Maintenance: The underdrain system must be inspected and cleaned periodically to prevent blockages that could disrupt flow distribution during filtration and backwashing. Operators should also check for signs of wear or damage that could compromise the system’s performance.

- Data Logging and Analysis: Keeping detailed records of system performance indicators, such as headloss, TOC removal, and flow rates, is critical for long-term system management. Operators should analyze these trends to identify potential issues before they impact system performance.

Operator’s Tip: Maintenance isn’t just about fixing things when they break—great operators prevent problems before they start!

6.6 Real-World Case Study: Optimizing BAC Performance through Maintenance

At a large municipal water treatment plant, operators began to notice a gradual decline in the BAC system’s TOC removal efficiency and a corresponding increase in headloss. After reviewing operational data, they determined that media fouling and air binding were contributing to the performance issues. By adjusting the backwash sequence to include a longer air scour phase and increasing the backwash frequency, the operators were able to restore the system’s performance. This example highlights the importance of regular monitoring, data analysis, and proactive maintenance in optimizing BAC system performance.

6.7 Advanced Operational Adjustments and Troubleshooting

Managing Air Binding in BAC Systems

Air binding occurs when air becomes trapped in the filter media, leading to increased headloss, uneven flow, and reduced filtration efficiency. This can be caused by insufficient backwashing, gas formation within the biofilm, or negative pressure conditions. Advanced operators need to recognize and manage air binding effectively to maintain system performance.

- Causes of Air Binding:

- Biofilm Gas Formation: Microbial activity in the biofilm can generate gases such as methane, which become trapped in the media bed.

- Insufficient Backwash: If backwash processes are incomplete, air can remain trapped within the media.

- Negative Pressure: Sudden drops in pressure can introduce air into the filter bed.

- Detection of Air Binding:

- Increased Headloss: A spike in headloss across the filter media is a common sign of air binding.

- Flow Reduction: Air binding restricts water flow, leading to lower filtration capacity.

- Management Strategies:

- Hydraulic Bumps: Operators can temporarily increase flow to dislodge air pockets.

- Rest Periods: Introducing rest periods (e.g., 90 seconds) can help trapped air escape.

- Optimizing Air Scour: During backwash, proper air scour intensity should be used to prevent air from remaining trapped while ensuring the media is cleaned effectively.

Backwash Frequency Optimization

Regular backwashing is essential for removing accumulated solids and maintaining the health of the biofilm. Advanced operators must optimize backwash frequency to balance efficient contaminant removal and the preservation of the biofilm.

- Factors to Consider:

- Headloss Monitoring: Backwash frequency should be adjusted based on headloss thresholds (e.g., 8-10 psi), indicating when media clogging has occurred.

- Turbidity: Monitoring effluent turbidity helps determine when particulates are overwhelming the system.

- TOC Removal: Declining Total Organic Carbon (TOC) removal rates may indicate that the biofilm is overwhelmed, requiring a backwash.

- Advanced Backwash Techniques:

- Pulse Backwashing: Short bursts of air or water can be used between full backwashes to dislodge accumulated material without fully disrupting the biofilm.

- Multi-Stage Backwashing: Alternating between air scour and water backwash optimizes media cleaning without damaging biofilm growth.

Troubleshooting Media Fouling

Media fouling reduces the filter's capacity to adsorb contaminants and can lead to increased headloss. Understanding the causes of fouling and taking corrective actions is crucial for maintaining long-term performance.

- Types of Fouling:

- Particulate Fouling: Accumulation of suspended solids and organic matter.

- Biofilm Overgrowth: Excessive biofilm growth leads to uneven flow and reduced adsorption capacity.

- Chemical Fouling: Precipitation of chemicals, such as calcium or iron, can also clog the media.

- Advanced Troubleshooting Techniques:

- Backwash Performance Assessment: Operators should assess the quality of backwash water to determine if accumulated material is being properly removed.

- Hydraulic Bumps: These are useful to dislodge excess material without performing a full backwash.

- Chemical Cleaning: In cases of severe fouling, a chemical cleaning process using dilute acids or alkalis may be required to remove stubborn deposits.

Exam Reminder: Advanced operators can describe multiple causes of air binding and media fouling, and recommend the right backwash or cleaning sequence—know these for troubleshooting and certification!